| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Dongchong

Model Number : 1000-8000series

Certification : ISO,MTC,MSDS,ROHS,REACH,SGS

Place of Origin : Chongqing ,Dongchong

MOQ : 500-5000kg for different product

Price : negotiable

Payment Terms : TT/LC

Supply Ability : 10000 Tons per month

Delivery Time : 2-3days for stock , 7-10days for normal size .25-30days for customized size

Packaging Details : Wooden pallet , Wooden Box

Surface : Mill finish,mirror

Color : Silver, red ,Yellow ,Green or as your need

Alloy : 7075

Protection : Film on one side or both side , paper interleave

Usage : Construction , Industry

Temper : T6,T651

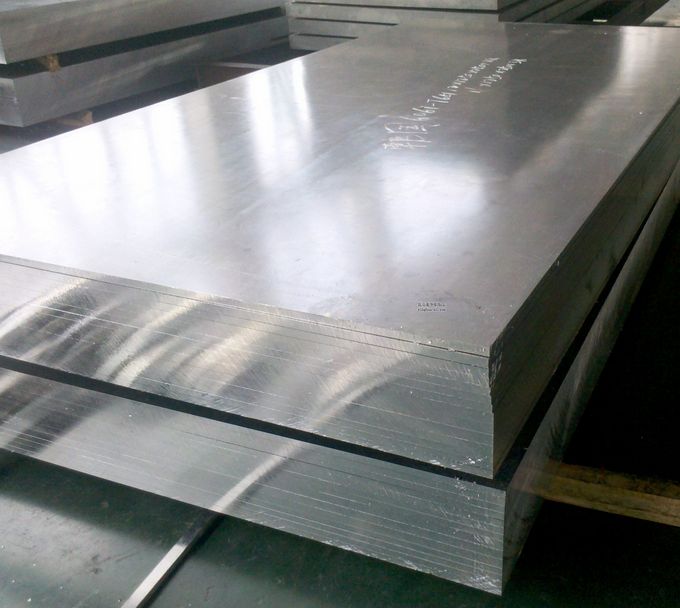

Mill Finish T6 T651 Sheet Aluminum Alloy Sheet for Sale 7075

Product Description

7000 series aluminium alloy represents 7075 mainly contains zinc element. Also belongs to aviation series, is Al-Mg-Zn-Cu alloy, is heat-treatable alloy, belongs to superhard aluminum alloy, has good wear resistance, also has good weldability, but poor corrosion resistance.

7000series aluminium alloy/ Aluminum-Zinc Alloy/ Aluminium-Zinc Alloy:7003,7005,7050,7075,etc

T heat treatment state (different from F, O, H state) is suitable for heat treatment, after (or without) work hardening to achieve stable products. T must be followed by one or more Arabic numerals. The first digit after T represents the basic type of heat treatment (from 1 to 10), and the subsequent digits indicate changes in the details of heat treatment. Such as 6061-T 62; 5083-H 343, etc.

7075 is used to manufacture aircraft structures and futures. It requires high stress structural parts and moulds with high strength and corrosion resistance.

CHEMICAL COMPOSITION (%)

| ALLOY | CHEMICAL COMPOSITION (%) | |||||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | |||

| 1035 | 0.35 | 0.6 | 0.1 | 0.05 | 0.05 | __ | __ | 0.1 | 0.03 | __ | 0.03 | __ | 99.35 | |

| 1100 | 0.95 | 0.05-0.2 | 0.05 | __ | __ | __ | 0.1 | __ | __ | 0.05 | 0.15 | 99 | ||

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | __ | __ | 0.05 | 0.03 | __ | 0.03 | __ | 99.5 | |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.05 | __ | __ | 0.05 | 0.03 | __ | 0.03 | __ | 99.6 | |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | __ | __ | 0.04 | 0.03 | __ | 0.03 | __ | 99.7 | |

| 1080 | 0.15 | 0.15 | 0.03 | 0.02 | 0.02 | __ | __ | 0.03 | 0.03 | __ | 0.02 | __ | 99.8 | |

| 1045 | 0.3 | 0.45 | 0.1 | 0.05 | 0.05 | __ | __ | 0.05 | 0.03 | __ | 0.03 | __ | 99.45 | |

| 1145 | 0.15 | 0.3-0.5 | 0.02 | 0.05 | 0.05 | __ | __ | 0.1 | 0.03 | __ | 0.03 | __ | 99.35 | |

| 1200 | 1 | 0.05 | 0.05 | __ | __ | __ | 0.1 | 0.05 | __ | 0.05 | 0.15 | 99 | ||

| 1235 | 0.65 | 0.05 | 0.05 | 0.05 | __ | 0.1 | 0.06 | __ | 0.03 | __ | 99.35 | |||

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | rest | |||

| 2A12 | 0.5 | 0.5 | 3.8~4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.3 | 0.15 | __ | 0.05 | 0.15 | rest | ||

| 2017 | 0.2-0.8 | 0.7 | 3.5-4.5 | 0.4-1.0 | 0.4-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | rest | |||

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | rest | |||

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | 0.05 | 0.15 | rest | ||||||

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | __ | __ | 0.25 | __ | __ | 0.05 | 0.15 | rest | |

| 3104 | 0.6 | 0.8 | 0.05-0.25 | 0.8-1.4 | 0.8-1.3 | __ | __ | 0.25 | 0.1 | __ | 0.05 | 0.15 | rest | |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | __ | 0.4 | 0.1 | __ | 0.05 | 0.15 | rest | |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | __ | 0.1 | __ | __ | 0.05 | 0.15 | rest | |

| 5A06 | ≤0.40 | 0.000~0.400 | ≤0.10 | 0.50~0.8 | 5.8~6.8 | __ | 0.0001~0.005 | ≤0.20 | 0.02~0.10 | __ | 0.05 | 0.1 | rest | |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | __ | 0.25 | __ | __ | 0.05 | 0.15 | rest | |

| 5050 | 0.4 | 0.7 | 0.2 | 0.1 | 1.1-1.8 | 0.1 | __ | 0.25 | __ | __ | 0.05 | 0.15 | rest | |

| 5154 | 0.25 | 0.4 | 0.1 | 0.1 | 3.1-3.9 | 0.15-0.35 | 0.25 | 0.2 | 0.05 | 0.15 | rest | |||

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | __ | 0.2 | 0.15 | __ | 0.05 | 0.15 | rest | |

| 5454 | 0.25 | 0.4 | 0.1 | 0.5-1.0 | 2.4-3.0 | 0.05-0.2 | 0.25 | 0.2 | 0.05 | 0.15 | rest | |||

| 5182 | 0.2 | 0.35 | 0.15 | 0.2-0.5 | 4.0-5.0 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | rest | |||

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | _ | 0.25 | 0.15 | __ | 0.05 | 0.15 | rest | |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | rest | |||

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | 0.05 | 0.15 | 0.1 | 0.05 | 0.15 | rest | |||

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | __ | 0.25 | 0.15 | __ | 0.05 | 0.15 | rest | |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | __ | 0.1 | 0.1 | __ | 0.05 | 0.15 | rest | |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | __ | 5.1-6.1 | 0.2 | __ | 0.05 | 0.15 | rest | |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.15-0.4 | 0.2 | 0.05 | 0.05 | __ | 0.01 | 0.08 | __ | 0.05 | 0.15 | rest | |

| 8079 | 0.05~0.3 | 0.7~1.3 | 0.05 | __ | __ | __ | __ | 0.1 | __ | 0.05 | 0.15 | rest | ||

Product Photo

Company Introduction

Chongqing Dongchong Aluminum Co,Ltd. Established in 2002,located in Industrial Park ,Xipeng

Town,Jiulongpo District,Chongqing City . We are supplier of Aluminum coil,foil,strip,sheet,tube,bar or

as customer’s requirement.

Our Advantage are precise facility,responsible and good worker ,big stock for

regular size ,fast delivery, best service even you buy one piece,quick response for each requirement.

In overseas market ,We exported to Saudi Arabia,Malaysia , Singapore , United states ,

Netherlands ,Colombia,Germany,Canada,Korea,ect.

In Domestic market ,we cooperated with FOXCONN GROUP,SWA GROUP,KEDALI GROUP ,ect.

ISO ,SGS,MSDS,SVHC,ROSH report can be guarantee quality by third party .

|

|

Blue Mill Finish Aluminum Sheet Metal , 7075 T6 Aluminum Plate Wear Resistance Images |